How to Use a Circular Saw: 7 Secrets You Should Know Before Cutting

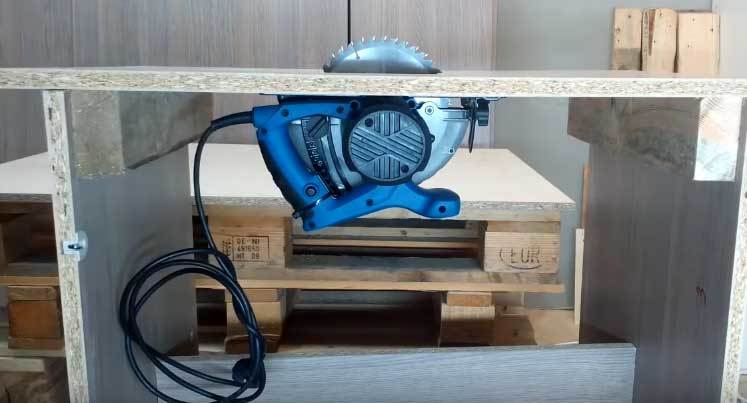

Circular saw is by far an amazing and powerful power tool. With a suitable blade, it can cut through wood, ceramic tiles, masonry, and even steel. However, with that much power, it becomes potentially dangerous to operate unless it’s handled carefully.

In the hands of a seasoned craftsman, the DIY possibilities with a circular saw are limitless. But in a novice hand, a portable circular saw, the sawdust emitting lout can cause severe harm if not used properly.

So to be able to easily and confidently operate the tool you need to learn the right way to use the tool. That’s where we come in, as we have done the hard work and found the right circular saw secrets and techniques for you to be confident while using the circular saw. Even these circular saw secrets can save your time, avoid any hazard and give professional clean and nice cut.

To succeed in clean, detailed, and un-splintered cuts. You need to follow these 7 circular saw secrets when using a circular saw. Let’s begin the work.

7 Circular Saw Secrets You Should Know Before Cutting

Examine your saw :

Examine the saw before every use. Check for any safety issues, like the blade guard holds its position. Inspect the blade itself for any broken or forced teeth. If the blade is somehow damaged, replace it. And Before changing the blade or even tightening or losing ,it is important to check to remove the power connection.

If you have a wired circular saw properly check the cord for any breaks and if using saw with a battery fully charge it before use.

Familiarize yourself with the saw, as there are many varieties and brands of the circular saw, with a somewhat similar basic design. You can use the circular saw for cutting composite material, metal sheet, or rolled steel bar beside only using the saw for lumber or other wood types only.

Using the right saw blade and in the right condition:

Using the right saw blade and in the right condition is important matter. You can say,this is rule of thumb to check if the blade selection is right. Because right blade gives always right cut .The cut depends on the state of the saw blade.

A rusty scratched or dismal blade for cutting, it will degrade the quality of the cut.Sometimes low quality cut due to wrong blade cause material wastage.

Use a carbide tipped blade to cut crosscuts and rip cuts. Correct the saw’s depth of cut thereupon the blade doesn’t extend more than ¼ inch past the board’s edge. Use the central lever to adjust the blade to needed cutting depth. Exposing more than ¼ of the blade will potentially be dangerous as it would have to work harder. Do it when the power is unplugged or battery removed.

Circular saw can also be used to cut many kinds of metals when fitted with the right blades. As well as masonries like stone and concrete.

Ensuring proper support for the material you’re cutting and unrestricted by any obstruction from beneath. This will eliminate perilous kickbacks, which can happen if the blade gets stuck in the cut. You can use a sawhorse available in different sizes in stores or just house a four long 2x4s beneath the sheet you are cutting. This facility will support your sheet while you cut.

The primary rule should be followed that is when cutting wood on sawhorses; you shouldn’t cut between them but outside the sawhorse duo. And cut in a way that the shorter piece falls away, whilst the sawhorse supports the longer piece. If you cut between the horses the lumber squeezes the blade.

Cut accurate rips :

Essentially, a rip cut is a cut that runs parallel to the grain to the wood. A rip cut works like a carving series shearing through the wood fiber. Circular saws do have a metal rip guide attached to the saw’s base but only works limited to about 6 inch wide rips.

You can opt for a better option and use a straightedge by clamping an 8 feet long board in place. A perfect saw guide can be the factory edge of the plywood as it is smooth and straight.

The piece you intend of ripping, mark it down and measure the distance of the blade to the edge of the base plate. Now press and screw the straightedge guide. Keep pressing the base plate beside the straightedge director while you make the cut.

Position the saw correctly :

When positioning the saw there isn’t any steadfast practice. Though the right thing to do is positioning the saw to the direction of a larger piece of board that’ll not fall down when cut. With this strategy, you won’t have to hold the pieces of cutout board and the saw’s base and the shoe will be entirely supported during the cut.

Simple and precise crosscuts :

A crosscut is a cut perpendicular or across the grain of the lumber. Circular saw is a perfect fit for cutting a precise square crosscut. To do that you just need to guide the saw with a layout square possibly a framing square or a speed square can also work. Use the square to guide the saw, place the square on the base plate and press against the edge. Now run the blade and make a smooth, square cut.

Prevent lumber splintering :

As the circular saw blade goes and comes out of the lumber it produces splinters. This occurs primarily while sawing pricey hardwood or veneer plywood. The way out of this mess is, position the board’s expensive side facing down.

This will save the veneer of the lumber and the splinters will occur on the actual backside. If you want to reduce splintering from both sides. Follow the same process of placing the most expensive or visible side facing downward and then with a sharp knife score along the boundaries.

On the scored line make a cut, the fibers will come off decent. With this technique, the wood will be splinter-free and charming on the cut.

Our Recommencement resource: